Ball bearings are precision-engineered components designed to reduce friction and support rotating shafts. They are standardized, globally available, and produced in a wide range of dimensions and specifications. Customers typically choose ball bearings based on load rating (kN), dimensions (mm), tolerance class, and sealing options.

Whether you need a miniature bearing for instrumentation, a deep groove ball bearing for motors, or a hybrid ceramic bearing for high-speed spindles – there is a standardized product series that fits your application.

Product Design and Features

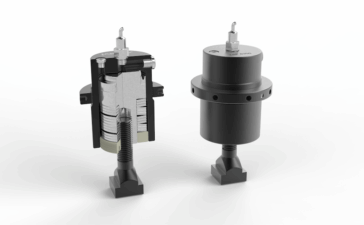

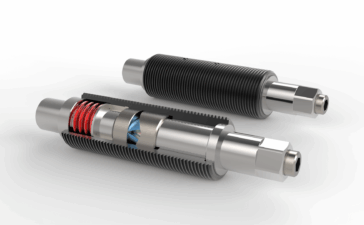

A standard ball bearing consists of:

- Inner and outer rings – hardened steel or stainless steel, machined to ISO standards.

- Rolling elements (balls) – steel or ceramic, precision-ground.

- Cage – steel, brass, or polymer, spacing the balls evenly.

- Seals/shields – metal shields (ZZ) or rubber seals (2RS) for protection.

Key product parameters include:

- Bore diameter (d), outer diameter (D), width (B)

- Dynamic load rating (Cr) and static load rating (C0r)

- Limiting speeds (oil vs. grease lubrication)

- Tolerance classes (ISO, ABEC, JIS)

Product Types and Series

1. Deep Groove Ball Bearings

- The most common product type, available from bore 1 mm up to several hundred mm.

- Product codes: 6000 series (standard), 6200 series (high load), 6300 series (extra high load), 6800/6900 series (thin-section).

- Options: open, shielded (ZZ), sealed (2RS).

- Applications: electric motors, pumps, gearboxes, household appliances.

2. Angular Contact Ball Bearings

- Designed for combined radial and axial loads.

- Available in single-row, double-row, or four-point contact versions.

- Product codes: 70xx, 72xx, 73xx series.

- Applications: machine tool spindles, automotive gearboxes.

3. Self-Aligning Ball Bearings

- Spherical outer raceway allows misalignment.

- Product codes: 12xx, 13xx series.

- Applications: agricultural machinery, conveyor systems.

4. Thrust Ball Bearings

- Axial load capacity in one or two directions.

- Product codes: 511xx, 512xx, 513xx.

- Applications: automotive clutches, rotary tables.

5. Miniature and Instrument Ball Bearings

- Bore diameters from 1 mm to 10 mm, outer diameters up to 30 mm.

- Often high precision (ABEC 5/7) with low noise.

- Applications: robotics, dental drills, small motors, gyroscopes.

6. Hybrid and Ceramic Bearings

- Hybrid: steel rings + ceramic balls (Si3N4).

- Full ceramic: both rings and balls made of advanced ceramic.

- Benefits: lower weight, higher speeds, electrical insulation, reduced wear.

- Applications: aerospace, medical devices, precision spindles.

Specifications and Standards

Ball bearings are globally standardized to simplify selection and interchangeability:

- Dimensions: ISO 15 / DIN 625

- Tolerances: ISO 492 / ABEC scale

- Load ratings & life: ISO 281

- Material standards: SAE 52100 (100Cr6 steel), AISI 440C (stainless)

Typical specification sheet for a product includes:

- Type/series (e.g. 6205-2RS)

- Dimensions (25 × 52 × 15 mm)

- Dynamic load rating Cr (14.8 kN)

- Static load rating C0r (7.8 kN)

- Max speed with grease/oil (e.g. 12,000 / 18,000 rpm)

- Sealing type: 2RS (rubber seals both sides)

Applications by Product Group

- Automotive: wheel bearings, alternators, transmissions

- Industrial: pumps, compressors, gearboxes, conveyor rollers

- Aerospace: high-speed spindles, auxiliary systems

- Medical & precision devices: surgical tools, dental turbines, diagnostic equipment

- Consumer products: fans, washing machines, power tools

- Renewable energy: wind turbine generators, pitch control systems

Buying Considerations

When selecting a ball bearing, customers typically compare:

- Load ratings (kN) to ensure safety margin

- Speed limits (rpm) depending on lubrication and seals

- Tolerance/precision class for noise and vibration requirements

- Material choice for corrosion resistance or high-temperature performance

- Sealing options for clean operation vs. maximum speed

Conclusion

Ball bearings are not just a technical concept but a standardized product category available in thousands of series and variations. By understanding the key product types, specifications, and applications, engineers and buyers can quickly identify the right solution for their system. Whether selecting a 6000 series deep groove ball bearing, a miniature ABEC-7 precision bearing, or a hybrid ceramic spindle bearing, the product choice directly impacts reliability, efficiency, and lifetime.